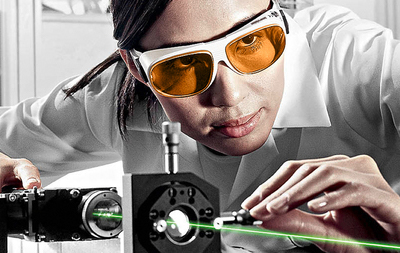

Laser safety eyewear (LSE) is not one-size-fits all. It is also not one pair protects all. Appropriate LSE is an important component of every laser safety program. LSE is designed to attenuate laser radiation to levels below the harmful threshold, known as the Maximum Permissible Exposure (MPE). Unlike other types of radiation (think ionizing radiation, like X-rays) where most day-to-day uses of that type only produce biological effects after cumulative exposures, serious laser injury from common applications can occur from a one-time acute injury. Effects like burns or eye injury. Those to the eye can be temporary or permanent, partial, or full. Therefore, it is critical that users of lasers understand how to properly identify the appropriate LPE for their application. Let’s consider some critical elements of LPE knowledge and selection.

Laser safety eyewear (LSE) is not one-size-fits all. It is also not one pair protects all. Appropriate LSE is an important component of every laser safety program. LSE is designed to attenuate laser radiation to levels below the harmful threshold, known as the Maximum Permissible Exposure (MPE). Unlike other types of radiation (think ionizing radiation, like X-rays) where most day-to-day uses of that type only produce biological effects after cumulative exposures, serious laser injury from common applications can occur from a one-time acute injury. Effects like burns or eye injury. Those to the eye can be temporary or permanent, partial, or full. Therefore, it is critical that users of lasers understand how to properly identify the appropriate LPE for their application. Let’s consider some critical elements of LPE knowledge and selection.

LSE should never be the first line of protection

Engineering and administrative/procedural controls must be in place to mitigate the chances of a personnel exposure to laser radiation. These controls include barriers around the laser setup, entryway barriers, window covers, proper beam termination, effective alignment processes and detailed procedures. A well-designed laser setup should eliminate or reduce the number of stray beams that could cause injury and should remove objects that could cause a direct or diffuse reflection of the beam.

LSE must protect against the laser wavelength being used

While this may seem like an obvious point, there are numerous examples of laser safety eyewear being used for a procedure or application that provide no actual protection to the user. The user of the laser must always verify that the pair of LSE they put on protects against the wavelength being transmitted. While LSE can be designed to protect against multiple wavelength ranges, no one pair will offer protection from all.

LSE must have an appropriate OD value for the application

Optical Density (OD) is the level of attenuation provided by the LSE filter material. LSE must have an appropriate OD value to reduce the laser radiation transmission through the eyewear to less than MPE levels. An example you might see on a pair of eyewear is OD 7+ @ 1064 nm.

LSE must have an appropriate Visual Light Transmission (VLT) value

LSE is meant to filter light and protect the eye. In doing so, the ability to see ambient light can also be affected. The user must be able to see through the eyewear with enough clarity to perform associated tasks. If the eyewear blocks too much ambient light, that can present a secondary hazard in the work area.

LSE must be properly labeled and in good condition

The wavelength range, OD, and VLT values must all be physically inscribed onto the frame or lens of the LSE. A label or ink that can be removed is not appropriate. Users must be able to quickly and easily identify whether the LSE is protective for their application. The LSE must be in good condition and show no signs of damage. LSE should be inspected periodically and insufficient or damaged LSE removed from use.

LSE must fit right

LSE should fit properly and be comfortable or they likely will not be worn at all times as is required. Eyewear comes in all different frame styles, including over-the-glasses and with prescription lenses.

Knowing how to choose proper LSE is a critical task for laser users.

Click here to learn more about laservision’s filter technology and to select the proper level of protection for your laser safety eyewear needs.