The goal in selecting laser safe eye protection is to provide comfortable and stylish eyewear that laser user personnel will wear with the proper protection levels (optical densities) that reduces potentially hazardous laser exposure to levels at or below maximum permissible exposure (MPE) levels.

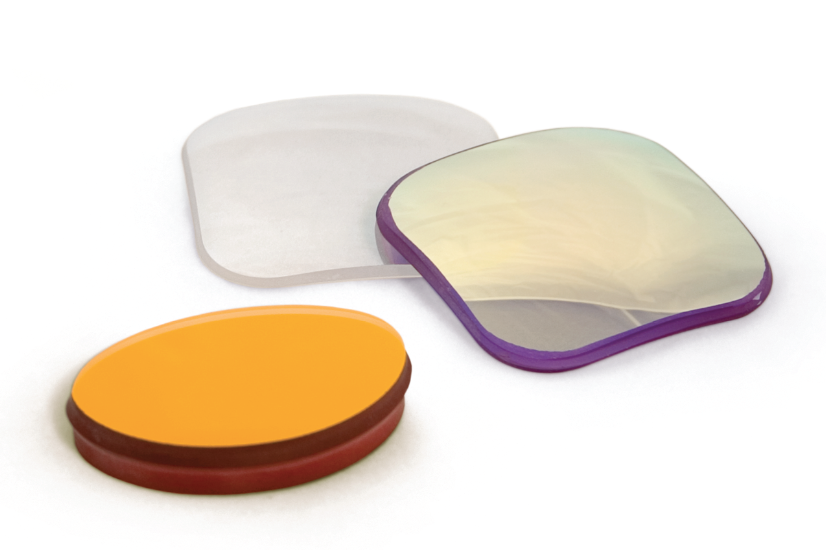

There is an ever-expanding array of complex and sophisticated laser systems in use today. Because of this our laser protective eyewear is available in a variety of technologies such as glass, polycarbonate, and nano spec (thin-film-coated glass).

Glass Filter Technology

All glass filters are produced at our advanced glass processing facility according to both ANSI and CE standards. With over fourteen glass filters, our selection of laser safety glass eyewear is unparalleled. Laservision Germany offers us access to 20 additional CE marked glass filters. Laservision has the capacity to develop custom glass filters specifically to your application requirements. Glass laser eyewear sets the standard in the moderate to high-power laser categories.

Glass filters offer:

- Superior optical properties

- Enhanced visible light transmission (VLT)

- Excellent color recognition

- High level of protection over broad range

Polycarbonate Filter Technology

We employ leading material science at our state-of-the-art production facilities to consistently manufacture the most advanced laser absorbers and coatings. Our development efforts have resulted in a complete line of polycarbonate laser eyewear. Many new filters by Laserervision have become the gold standard for polycarbonate protection.

Polycarbonate filters are:

- Lightweight

- Cost-effective

- Offered in a large variety of frame styles

- Best suited for low-mid power density laser applications

- Some are impact resistant, ANSI Z87 compliant

Thin-Film Coated Filter Technology

The advanced materials lab at laservision creates superior reflective coatings that offer the highest levels of protection and VLT for all laser applications. Our thin-film-coating (also referred to as nanospec) technology can be applied to both polycarbonate and glass lenses for any laser application. If your application demands advanced protection and excellent VLT, consider laservision thin-film laser eyewear as your solution.

Nanospec technology provides:

- High Optical Density* reflective coatings

- Premium VLT

- Excellent Color Recognition

- A solution to the challenge of picosecond and femtosecond pulse protection

- Protection for many low-high power densities laser applications

If you have questions or are uncertain of the protection you need, you can reach our laser safety experts at sales@lasersafety.com