Electromagnetic Radiation

Laser radiation is part of the electromagnetic spectrum. The electromagnetic spectrum includes X-rays and visible light microwaves. In fact, electromagnetic radiation is a natural phenomenon to which we are all exposed.

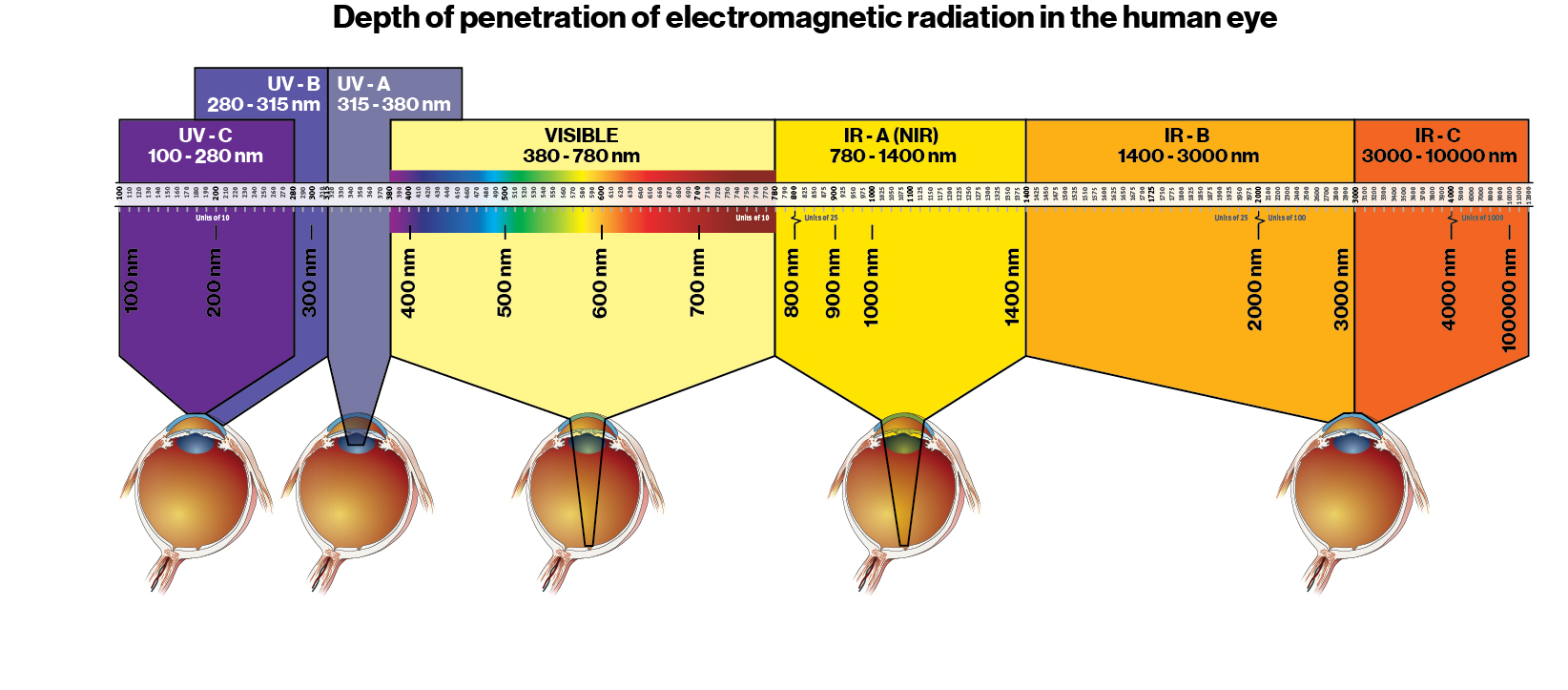

When electromagnetic radiation is within the range visible to the human eye, between 380 and 780 nm (nm = nanometer = one billionth of a meter), it is called visible light. This range is called the visible spectrum. When all wavelengths in the visible spectrum are emitted simultaneously, it is perceived as white light.

When white light falls on an optically dispersive element such as a prism or birefringent filter, you can see the visible spectrum due to refraction. It starts as the color violet, turning to blue, green, then yellow and finally, red. The wavelength increases as the color changes, with violet being the shortest wavelength and red the longest.

Why Laser Safety?

Even at lower power output levels, it is possible to cause irreversible ocular injury from a single accidental exposure to a direct or reflected laser beam, depending on the wavelength, output and exposure duration. Laser safety can prevent damage to equipment as well. An important factor in determining damage potential is irradiance, the power per area, expressed in watt/cm2.

What makes lasers dangerous compared to conventional light sources?

Laser beams have unique properties from natural light sources:

- Coherent – A fixed relation to time and space

- Monochromatic – All of the same wavelength

- Collimated – Can travel over great distances as a nearly parallel beam

Power or energy that impacts an area, such as the eye, is independent of the distance to the radiation source.

Wavelengths between visible light (380-780 nm) and near infrared wavelengths (700-1400 nm) are focused by a lens to a spot size—a factor of ten smaller than normal incoherent light. While the standard light bulb creates an image on the retina of approximately 100 µm, laser light can be reduced to a spot of just a few micrometers (~ 10 µm) in diameter. Therefore, the light quantity that hits the eye is concentrated on a much smaller spot. Due to the refractive and focusing properties of the eye, the retinal irradiance is a factor of 100,000. The power density (power per area or watts/cm2) resulting from this concentration could be sufficiently high to the point that any tissue in the focused area will be heated and rapidly destroyed. It is possible to lose your eyesight by one single laser pulse, since the fovea, which is responsible for sharp central vision and located on the retina, is the size of a few micrometers.

The eye is sensitive to radiation. Humans have developed natural protective mechanisms. When light appears too bright—the power density exceeds the damage threshold of the eye—we automatically turn away and close our eyes. This is the aversion response or blink reflex. This automatic reaction is effective for radiation up to 1mW of power. With higher power levels, too much energy reaches the eye before the blink reflex can respond, which can result in irreversible retinal damage. The near infrared wavelengths (700 – 1400 nm) are a type of radiation that is especially dangerous to the human eye, as we have no natural protection against it. The radiation advances to the retina, but the exposure is only noticed after the damage is done. Infrared radiation (1400 – 11000 nm) is absorbed in the surface of the eye. It leads to the overheating of tissue and burning or ablation of the cornea.

Laser Safety Regulations

Laser Categories According to ANSI Z136.1 and EN 60825-1

Lasers are categorized into seven hazard classes based on accessible emission limits (AELs). These limits indicate the hazard class of the laser and are listed in the American National Standards ANSI Z136.1 for Safe Use of Lasers and European Standard IEC 60825-1.

Laser Operating Modes per EN 60825-1 (November 2014) Laser Safety in the USA (ANSI Z136)

ANSI Z136 standard requires specification of eyewear according to Optical Densities (OD) and wavelength. ANSI also allows a Nominal Hazard Zone (NHZ) to be determined by the laser safety officer (LSO). Outside of the NHZ, diffuse viewing eyewear is allowed.

Laser Safety in Europe (EN207/208/60825)

European Norms (EN) are developed by a standard body, then left to each member country to adopt as its national regulations. As an example, Australia has adopted new laser safety regulations that are based on the European laser safety regulations (EN 207/EN208). EN 207 refers to full protection eyewear and EN208 is dedicated to alignment eyewear.

EN207

Laser eye protection products require direct hit testing and labeling of eye protectors with protection levels, such as D 10600 L5, where L5 reflects a power density of 100 MegaWatt/m2 as the damage threshold of the filter and frame during a 10 seconds direct hit test at 10,600 nm. Safety glasses, filter and frame must be able to withstand a direct hit from the laser for which they have been selected for at least ten seconds (continuous wave) or 100 pulses (pulsed mode).

EN 208

EN 208 refers to glasses for laser alignment. Laser safe eyewear for alignment reduces the actual incident power to the power of a class 2 laser (< 1 mW for continuous wave lasers). Class 2 lasers are regarded as eye-safe if the eye’s aversion response is working normally. Alignment glasses allow the user to see the beam spot while aligning the laser. This is only possible for visible lasers. According to EN 208, visible lasers are defined as having wavelengths between 400 nm to 700 nm. Alignment glasses must withstand a direct hit from the laser for which they have been selected, for at least ten seconds (continuous wave) or 100 pulses (pulsed mode).

EN 60825 Series

EN 60825 Series requires that laser safety eyewear provides sufficient optical density (OD) that reduces the power of a given laser to equal to or less than the listed Maximum Permissible Exposure levels (MPE). Providing protection according to OD alone is not sufficient when the material of the eyewear cannot withstand a direct hit. The EN 60825 Series, similar to the ANSI Z136, is made up of several application-based standards.

Daylight Transmission (VLT) and Color Vision

When we wear laser safety glasses, some wavelengths of the spectrum that would normally reach our eyes are filtered out. If we block light from the visible region, this inevitably changes our perception of our environment. First, the attenuation of transmission in the environment increases, causing a darkening effect—similar to the effect of sunglasses. Second, blocking certain wavelengths will change our perception of color.

VLT

The attenuation of light by a filter in the visible spectrum is defined as the visible light transmission (VLT) or luminous transmittance. As described in the ANSI standard Z136.7 for Testing and Labeling of Laser Protective Equipment, VLT is determined in relation to a standard illuminant. It is evaluated according to the spectral sensitivity of the eye to daylight-adapted (photopic) or night-adapted (scotopic). If the measured VLT value is less than 20%, the user should ensure that their working environment receives additional illumination. With a low VLT and inadequate illumination, the color vision is restricted and the spectral sensitivity of the eyes moves towards the shorter wavelengths.

Color Vision

An important aspect for the selection of a laser safety filter is color vision. Our eyes can adapt to different light situations. The total amount of light can be balanced by additional illumination. If color vision is impaired or restricted, some colors may not be recognized. This may effect how one sees control panel indicators, warning lights or displays, or the ability to distinguish between instruments or items marked by color such as those found in medical surroundings.

Shop Laser Eyewear

Browse through our laser safety eyewear using our filter search tool

Talk to Laser Safety Experts

Uncertain of the protection you need? Ask one of our Certified Laser Safety Experts today. 800-393-5565